NOTE: this is a repost of my thread on BudgetLightForum

here

I'm calling this light the Min/Max Light - minimum size, maximum functions. I used a Nitecore TIP2 as host for this and put every feature I could think of into it:

* RGB colors

* Cyan LASER

* 365nm UV

* Current and Voltage instrumentation with INA219

* Temperature monitoring & control

* OLED display

* Touch-sensitive controls for peek mode

* USB-C onboard charging

For a long time I've been carrying the

SDmini with OLED and got to a point where I couldn't stand to carry a light that didn't give me detailed battery and runtime information, but the 18650 format was often too large. I decided to build a very small EDC light that included every feature I've ever put into a flashlight in one, and in the minimum size possible. The Nitecore TIP2 was the perfect host with 500mAh cell size, onboard charging, and conveniently had two emitters side-by-side so I could remove one and add new emitter types.

The most difficult part of this was the optics setup - I had to fit optics for a collimated laser and the UV LED into the space left by removing one of the XP-G emitters and corresponding TIR from the stock light. Here's the completed setup, which involved heavy modification of the plastic frame and brass heatsink, as well as some custom structures formed from copper:

The TIR optic itself took some work too. I needed a flat lens for the laser beam, and the plastic material wouldn't pass 365nm UV, so I carved out the TIR lens and installed a small glass window, secured in place with epoxy:

In the back I removed one of the two magnets and used the space to put in a USB-C jack and a charger based on the LTC4054:

The laser is built as small as possible using 7mm optics from cheap red laser modules just like I did in my

Nitecore Tube Laser, and in this case using a 505nm cyan laser diode. Even built this small, the battery had to be moved back to make room for the laser assembly. For this reason I had to separate the protection circuit and put it on the side. In this image the laser boost driver and LED drivers are also in place:

The back end also gets a programming port to update firmware without disassembly:

And a 3D-printed cover held on by a screw:

After quite a bit more wiring with 34AWG magnet wire, here's all the electronics in place, with some annotations. The battery monitoring is accomplished by an INA219 power monitor and the control is a PIC18F26K40 on a custom board that includes support circuitry for the 128x32 OLED display:

And with the display board folded down into place it is ready to be put into the housing:

The housing needed a window to be milled out for the display:

And finished with needle files:

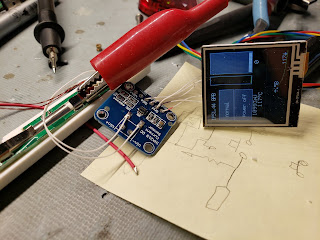

This light includes something I've been adding to all my lights with displays - peek mode. With this function you can tap on the the buttons (without actually pressing them) and see the battery status on the display. To do this, I add a capacitive touch sensor behind the buttons by covering the back side with copper foil tape which gets connected to the TTP223:

Finally the internals can be slid into the housing. I also added a 0.5mm-thick plexiglas window over the display, and then program it:

And power it up:

And here's what the UV looks like:

And a head-on view of the front. You can see the TIR for the white beam, the laser, the UV, and on the lower side of the TIR you can see where the de-domed XML-RGBW contacts the optic to get RGB light out the front:

I should probably do a video or something to explain more about the firmware features - there's a lot going on in this one. In short, it is 2-button MELD interface with the display showing mode, drive level, drive current, battery charge status, LED temperature, battery voltage, battery capacity remaining, and estimated runtime. While charging it shows charge status, voltage, and current. In peek mode it shows charge status, battery voltage, and a preview of the mode that will run if it is turned on.

Thanks for reading